Canada’s rapidly evolving robotics ecosystem is transforming traditional industries and creating unprecedented opportunities for business growth. From advanced manufacturing facilities in Ontario to innovative automation solutions in British Columbia, robotics and automation technologies are revolutionizing how Canadian businesses operate, compete, and scale globally.

The convergence of artificial intelligence, machine learning, and sophisticated robotics has positioned Canada as a leading force in Industry 4.0. With investments in robotics reaching record levels and automation adoption accelerating across sectors, Canadian companies are leveraging these technologies to enhance productivity, ensure workplace safety, and maintain competitive advantages in the global marketplace.

As labor shortages persist and operational costs rise, robotics and automation offer practical solutions for businesses seeking sustainable growth. Industry leaders project the Canadian robotics market to exceed $5 billion by 2025, driven by innovations in collaborative robots, autonomous systems, and smart manufacturing solutions. This technological revolution presents both opportunities and challenges for business leaders, policymakers, and workforce development strategies.

The Current State of Canadian Robotics and Automation

Market Size and Growth Trends

The robotics and automation industry continues to experience remarkable growth, with the global market expected to reach $395.7 billion by 2025. Recent Canadian innovation trends show particular strength in collaborative robots and industrial automation solutions, contributing significantly to this expansion.

In Canada, the automation sector has demonstrated a compound annual growth rate of 12.3% since 2020, driven by increasing adoption across manufacturing, healthcare, and logistics sectors. Ontario and Quebec lead this growth, accounting for approximately 60% of the country’s robotics market share.

Small and medium-sized enterprises (SMEs) are increasingly embracing automation solutions, with a 25% uptick in robot installations over the past two years. This trend is particularly evident in food processing, automotive components, and electronics manufacturing.

According to industry experts, the COVID-19 pandemic has accelerated automation adoption, with Canadian businesses investing heavily in robotics to ensure operational resilience. Market analysis indicates that collaborative robots (cobots) represent the fastest-growing segment, projected to expand by 15.7% annually between 2023 and 2027.

Leading Canadian Innovation Hubs

Canada’s robotics and automation landscape is anchored by several world-class innovation hubs strategically positioned across the country. The MaRS Discovery District in Toronto stands as North America’s largest urban innovation hub, housing numerous robotics startups and research initiatives. This facility has become a cornerstone for collaborative development between entrepreneurs, researchers, and industry leaders.

In Waterloo, the Waterloo Robotics Institute leads groundbreaking research in autonomous systems and human-robot interaction. The facility’s partnership with local technology companies has established the region as a premier destination for robotics development.

Montreal’s Artificial Intelligence and Robotics Hub combines Quebec’s strong manufacturing heritage with cutting-edge AI capabilities. The center has attracted significant international investment and houses several pioneering robotics companies.

Vancouver’s Technology Hub and Calgary’s Robotics Innovation Centre represent emerging powerhouses in the West, focusing on industrial automation and agricultural robotics respectively. These facilities offer state-of-the-art testing environments, mentorship programs, and access to venture capital networks.

The National Research Council’s Advanced Manufacturing program, with facilities across Canada, provides crucial support for robotics research and commercialization, ensuring Canadian innovations remain globally competitive.

Transformative Applications in Key Industries

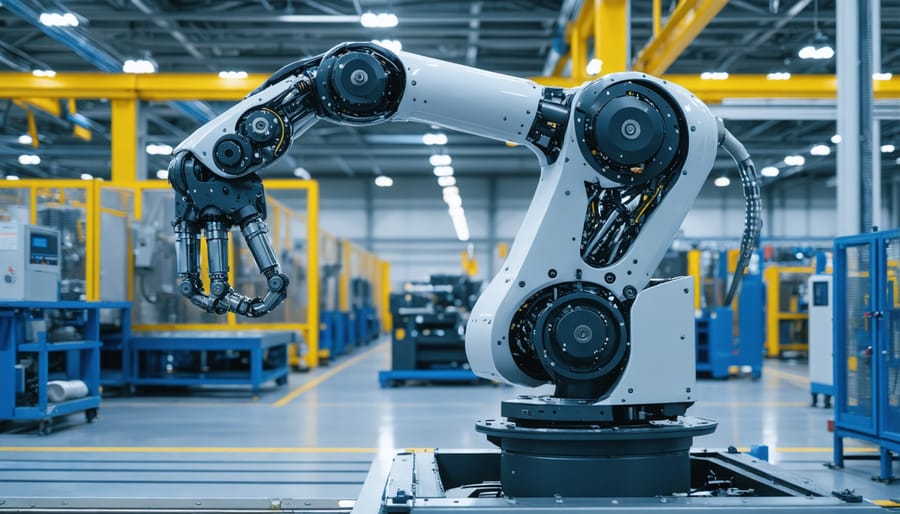

Manufacturing Automation Success Stories

Canadian manufacturers have demonstrated remarkable success in implementing automation solutions across various sectors. Magna International, based in Aurora, Ontario, revolutionized their automotive parts production by introducing collaborative robots, resulting in a 40% increase in productivity and 25% reduction in operational costs.

ATS Automation in Cambridge showcases another compelling example, where their implementation of advanced manufacturing cells in medical device assembly led to 99.9% quality consistency and doubled production capacity. Their success has attracted international attention and established new industry benchmarks.

In the food processing sector, Maple Leaf Foods’ state-of-the-art facility in Hamilton represents one of North America’s most technologically advanced protein processing plants. Their automated systems handle everything from sorting to packaging, improving food safety standards while reducing waste by 30%.

Vancouver-based Precision NanoSystems demonstrates how automation benefits the pharmaceutical industry. Their automated manufacturing platform for genetic medicines decreased production time by 65% while maintaining strict quality controls. “Automation has been transformative for our operations,” notes Dr. Sarah Chen, their Director of Manufacturing.

Small and medium-sized enterprises are also achieving significant gains. Montreal’s Vention, a manufacturing automation platform provider, helped numerous local manufacturers implement modular automated solutions, resulting in average productivity increases of 35% within the first year of deployment.

These success stories highlight a common thread: strategic automation implementation leads to improved efficiency, quality, and competitiveness. The key factors contributing to their success include careful planning, workforce training, and phased implementation approaches.

Emerging Applications in Healthcare and Agriculture

The integration of robotics in healthcare and agriculture is revolutionizing these essential sectors across Canada. Recent healthcare automation innovations have led to remarkable improvements in patient care, with surgical robots enabling more precise procedures and automated pharmacy systems enhancing medication management.

In Canadian hospitals, autonomous mobile robots now handle routine tasks like delivering supplies and sanitizing facilities, allowing healthcare professionals to focus more on patient care. These solutions have proven particularly valuable in reducing exposure risks during public health emergencies and streamlining workflow in busy medical facilities.

The agricultural sector is experiencing equally transformative changes. Smart farming robots are helping Canadian farmers optimize crop yields and reduce resource waste. Automated systems for seeding, irrigation, and harvesting are becoming increasingly common across the prairies, with Ontario-based companies leading the development of AI-powered crop monitoring drones.

British Columbia’s greenhouse operations showcase how robotics can enable year-round production through automated climate control and precise plant care. These systems can adjust growing conditions in real-time, resulting in higher yields and more sustainable farming practices.

Notable success stories include Edmonton’s Pigeon Lake Farms, which increased production efficiency by 40% after implementing automated harvesting systems. Similarly, Vancouver General Hospital’s implementation of robotic surgical assistants has reduced recovery times by 30% for certain procedures.

Industry experts predict that by 2025, these applications will become standard practice, with Canadian companies positioned to be global leaders in agricultural and healthcare automation solutions. Government support through innovation grants and research partnerships continues to accelerate development in these sectors.

Investment and Support Landscape

Government Initiatives and Funding Programs

Canadian businesses exploring robotics and automation solutions can access numerous government funding initiatives designed to accelerate technological adoption. The federal government’s Strategic Innovation Fund offers significant support for large-scale automation projects, while the Industrial Research Assistance Program (IRAP) provides both funding and technical expertise for SMEs implementing robotics solutions.

Provincial programs complement federal initiatives, with Ontario’s Regional Development Program and Quebec’s Innovation Program offering targeted support for manufacturing automation. These programs, along with various digital adoption support programs, can cover up to 50% of eligible project costs.

The Scientific Research and Experimental Development (SR&ED) tax incentive program remains a cornerstone of innovation funding, offering tax credits for companies developing or implementing novel robotics solutions. Additionally, the Canada Job Grant helps organizations train employees on new automated systems, covering up to two-thirds of training costs.

Business Development Bank of Canada (BDC) provides specialized financing solutions for automation projects, including flexible terms and advisory services. The bank’s Industry 4.0 adoption program offers particularly attractive terms for manufacturers investing in smart technologies and robotics integration.

Companies can also leverage support from innovation hubs like MaRS and Communitech, which provide guidance on accessing these funding opportunities and connecting with industry experts for project implementation.

Private Sector Investment Trends

The robotics and automation sector continues to attract substantial private investment, with venture capital firms and corporate investors showing increased confidence in Canadian innovation. In 2023, investment in Canadian robotics startups reached $1.2 billion, marking a 45% increase from the previous year.

Notable Canadian success stories include Toronto-based Attabotics, which secured $95 million in Series C funding for their warehouse automation solutions, and Vancouver’s A&K Robotics, attracting $38 million for their autonomous cleaning robots. These investments demonstrate growing confidence in Canadian technological capabilities and market potential.

According to Marie Lambert, partner at Maple Leaf Ventures, “Canadian robotics companies are particularly attractive to investors due to their focus on practical applications and strong R&D foundations.” Corporate investors, including major manufacturers and technology companies, are increasingly participating in funding rounds, often combining financial investment with strategic partnerships.

Key investment trends include:

– Rising interest in collaborative robot solutions

– Increased funding for AI-integrated robotics platforms

– Growing investment in robotics-as-a-service (RaaS) models

– Strong focus on sustainability-oriented automation solutions

The average deal size has grown significantly, with Series A rounds now typically ranging from $5-15 million, reflecting the maturing nature of the industry. Early-stage investments remain robust, with angel investors and accelerators actively supporting innovative robotics startups across the country.

Workforce Impact and Adaptation

Skills Development and Training Programs

Canada offers diverse opportunities for skills development in robotics and automation through industry-led training programs and educational partnerships. Leading institutions like the Canadian Robotics Training Centre and NAIT’s Centre for Advanced Technologies provide hands-on training in robot programming, maintenance, and system integration.

Several government initiatives support workforce development, including the Canada Job Grant, which covers up to 66% of training costs for employers investing in their employees’ robotics skills. The Strategic Innovation Fund also allocates resources specifically for automation-related training programs.

Major robotics manufacturers operating in Canada, such as FANUC and ABB, offer certified training programs that combine theoretical knowledge with practical experience. These programs typically range from basic operation to advanced programming and maintenance certification.

Online learning platforms have emerged as valuable resources, with organizations like MaRS Discovery District and Innovation Hub offering flexible, self-paced courses in robotics and automation fundamentals. These programs are particularly beneficial for professionals seeking to upgrade their skills while maintaining full-time employment.

Industry associations like the Robotics Industry Association of Canada regularly organize workshops, seminars, and certification programs. These events not only provide technical training but also offer networking opportunities with industry experts and potential employers.

For businesses implementing automation solutions, many system integrators provide comprehensive training packages as part of their installation services, ensuring smooth transition and optimal system operation.

Job Creation and Evolution

While concerns about job displacement persist, the robotics and automation industry is actually creating numerous high-value employment opportunities across Canada. Recent studies by the Canadian Advanced Technology Alliance show that for every robot installed, approximately 2.5 new jobs are created in related fields.

These emerging roles include robotics engineers, automation specialists, AI trainers, robot maintenance technicians, and integration consultants. Companies like Kinova Robotics in Quebec have demonstrated this trend, expanding their workforce by 40% in the past two years while developing innovative robotic solutions.

The evolution of the job market has sparked new educational programs at institutions such as the University of Waterloo and British Columbia Institute of Technology, preparing the next generation for careers in robotics and automation. Industry experts predict particularly strong growth in collaborative robotics programming, where humans and robots work together to optimize productivity.

Canadian manufacturers are increasingly seeking skilled professionals who can manage automated systems, analyze data, and improve operational efficiency. Small and medium-sized enterprises are creating positions for automation coordinators who can oversee the integration of robotic systems into existing operations.

The federal government’s investment in upskilling programs and innovation hubs further supports this job creation trend, ensuring Canadian workers can adapt to and benefit from technological advancement in the workplace.

The robotics and automation industry in Canada stands at a pivotal moment of unprecedented growth and opportunity. As we’ve explored throughout this article, the sector continues to demonstrate remarkable resilience and innovation, with Canadian companies leading breakthrough developments in manufacturing, healthcare, and agricultural automation.

The future outlook remains exceptionally positive, with projections indicating sustained growth in automation adoption across multiple sectors. Canadian businesses are increasingly recognizing the competitive advantage that robotics and automation provide, from improved operational efficiency to enhanced workplace safety and productivity gains.

Key success factors for businesses entering or expanding in this space include maintaining a balance between technological advancement and workforce development, investing in continuous innovation, and leveraging available government support programs. The collaboration between industry, academia, and government institutions continues to strengthen, creating a robust ecosystem for robotics and automation development.

Looking ahead, emerging technologies like AI-enhanced robotics, collaborative robots, and smart manufacturing solutions are expected to drive the next wave of industry evolution. Canadian companies are well-positioned to capitalize on these opportunities, supported by our strong technical expertise, innovative business culture, and strategic government initiatives.

For business leaders and investors, the time to engage with robotics and automation is now. With proper planning, strategic implementation, and a commitment to continuous learning, Canadian organizations can successfully navigate the transformation toward an automated future while maintaining their competitive edge in the global market.