Supply chain optimization demands strategic precision in today’s volatile global marketplace. As supply chain globalization trends reshape Canadian business operations, companies face unprecedented challenges in maintaining efficiency, reducing costs, and ensuring reliable delivery. From inventory management to logistics coordination, the complexity of modern supply networks requires sophisticated solutions backed by data-driven insights and proven methodologies.

Leading Canadian manufacturers and distributors have demonstrated that successful optimization hinges on three critical factors: real-time visibility across all supply chain nodes, adaptive planning capabilities that respond to market fluctuations, and seamless integration of digital technologies. By addressing these core elements, businesses can transform supply chain challenges into competitive advantages.

Recent industry analysis reveals that companies implementing comprehensive optimization strategies achieve 15-25% cost reductions while significantly improving customer satisfaction rates. For Canadian businesses competing in the global marketplace, mastering supply chain optimization isn’t just about operational efficiency—it’s about creating resilient, future-ready organizations capable of thriving amid uncertainty.

Common Supply Chain Optimization Challenges in Global Trade

Inventory Management Complexities

Managing inventory across multiple global locations presents unique challenges for Canadian businesses, particularly when dealing with e-commerce supply chain challenges. Companies must balance holding costs with customer demand while accounting for varying lead times across different regions.

According to Supply Chain Canada, businesses typically struggle with three key inventory management aspects: demand forecasting accuracy, safety stock optimization, and warehouse space utilization. These challenges are amplified when managing inventory across multiple time zones and regulatory environments.

Canadian retailers like Lululemon have successfully tackled these complexities by implementing advanced inventory management systems that provide real-time visibility across their global network. Their approach combines data analytics with strategic positioning of distribution centers to optimize stock levels and reduce carrying costs.

Effective inventory management requires careful consideration of seasonal variations, local market preferences, and transportation costs. Successful businesses often employ a mix of centralized and decentralized inventory strategies, supported by robust technology solutions that enable quick response to market changes and maintain optimal stock levels across all locations.

Transportation Network Issues

Transportation networks form the backbone of modern supply chains, yet they present significant coordination and cost optimization challenges for Canadian businesses. Companies often struggle with route planning inefficiencies, fluctuating fuel costs, and the complexities of multi-modal transportation management.

According to the Canadian Transportation Alliance, businesses lose an average of 12% in potential revenue due to suboptimal logistics coordination. Weather disruptions, particularly during harsh winter months, further complicate transportation planning across provinces.

Leading logistics expert Sarah Thompson of TransCan Solutions notes, “Successful companies are increasingly adopting dynamic routing systems and real-time tracking solutions to overcome these challenges. The key is finding the right balance between cost efficiency and delivery reliability.”

To optimize transportation networks, businesses should focus on:

– Consolidating shipments to maximize vehicle capacity

– Implementing flexible routing systems

– Developing contingency plans for seasonal challenges

– Leveraging cross-docking opportunities

– Building strong relationships with multiple carriers

Canadian manufacturers like Northern Steel have demonstrated success by implementing hybrid transportation models, combining dedicated fleet operations with third-party logistics providers to maintain flexibility while controlling costs.

Technology-Driven Solutions for Modern Supply Chains

AI and Machine Learning Applications

Artificial Intelligence and Machine Learning are transforming supply chain optimization, offering unprecedented capabilities in prediction, automation, and decision-making. Canadian companies like Kinaxis and Blue Yonder have demonstrated the power of AI-driven solutions in revolutionizing supply chain management.

AI applications in supply chain optimization include demand forecasting, inventory management, route optimization, and predictive maintenance. Machine learning algorithms analyze historical data, market trends, and external factors to predict demand patterns with remarkable accuracy, helping businesses maintain optimal inventory levels and reduce carrying costs.

Notable success stories include Vancouver-based Pressboard Media, which implemented AI-powered supply chain solutions to reduce delivery times by 35% and cut operational costs by 28%. Similarly, Toronto’s Metro Supply Chain Group leverages machine learning to optimize warehouse operations and automate order fulfillment.

These technologies excel in real-time decision making, processing vast amounts of data to identify potential disruptions before they occur. AI systems can automatically adjust supply chain parameters, suggest alternative suppliers, and optimize delivery routes based on current conditions.

For Canadian businesses, AI integration has become increasingly accessible through cloud-based solutions and partnerships with technology providers. The ROI is compelling – companies report average efficiency improvements of 15-25% within the first year of implementation, with enhanced accuracy in demand forecasting reaching up to 85%.

Looking ahead, emerging AI capabilities in natural language processing and computer vision are opening new possibilities for supply chain automation and optimization.

Real-time Tracking and Analytics

Modern supply chain management demands precise, real-time visibility into every aspect of operations. Canadian businesses are increasingly adopting sophisticated tracking and analytics systems to maintain competitive advantages in global markets. These digital trade solutions provide instant insights into inventory levels, shipment status, and potential disruptions.

Leading Canadian logistics provider, MetroLine Solutions, implemented real-time tracking across their nationwide network, resulting in a 30% reduction in delivery delays and improved customer satisfaction. Their system combines GPS tracking, IoT sensors, and predictive analytics to monitor shipments, warehouse conditions, and fleet performance.

Key components of effective real-time tracking systems include:

– Cloud-based dashboard integration

– Mobile accessibility for stakeholders

– Automated alert systems

– Performance metrics monitoring

– Predictive analytics capabilities

These systems enable businesses to:

– Identify bottlenecks quickly

– Respond to disruptions proactively

– Optimize inventory levels

– Improve delivery accuracy

– Enhance customer communication

According to Sarah Chen, Supply Chain Director at Canadian Tire, “Real-time analytics have transformed our ability to make informed decisions. We can now adjust our operations within hours instead of days, significantly improving our response to market changes.”

For implementation success, businesses should start with clear objectives, ensure proper staff training, and gradually expand system capabilities based on operational needs and feedback.

Canadian Success Stories in Supply Chain Innovation

Canadian companies have demonstrated remarkable success in revolutionizing their supply chain operations, setting benchmarks for global innovation. Shopify, the Ottawa-based e-commerce giant, transformed its fulfillment network by implementing advanced AI-driven inventory management systems, resulting in a 40% reduction in shipping times and a 25% decrease in logistics costs.

Montreal-based Metro Supply Chain Group showcases another compelling example of supply chain excellence. By developing a proprietary blockchain-based tracking system, they achieved end-to-end visibility across their operations. This innovation led to a 30% improvement in inventory accuracy and significant reduction in transit delays, particularly crucial during the challenging pandemic period.

Maple Leaf Foods’ supply chain transformation stands out for its sustainability focus. The company implemented an integrated planning system that optimized both distribution efficiency and environmental impact. Their initiative reduced transportation emissions by 20% while maintaining product freshness and delivery reliability.

Canadian Tire’s digital transformation of its supply chain operations exemplifies strategic innovation. By investing in automated distribution centers and implementing predictive analytics, they reduced order processing time by 50% and improved inventory turnover by 35%. Their success demonstrates how traditional retailers can adapt to modern supply chain challenges.

West Coast-based Lululemon’s agile supply chain strategy has become a case study in flexibility and responsiveness. Their implementation of real-time inventory tracking and dynamic routing systems enabled them to maintain 98% order fulfillment rates despite global supply chain disruptions.

“Canadian companies are increasingly leading the way in supply chain innovation,” notes Dr. Sarah Thompson, Supply Chain Management Professor at the University of Toronto. “Their success stems from combining technological advancement with practical implementation strategies.”

These success stories share common elements: strategic technology adoption, focus on data-driven decision making, and commitment to continuous improvement. Small and medium-sized enterprises can learn from these examples by starting with targeted improvements in their most critical supply chain areas and gradually expanding their optimization efforts.

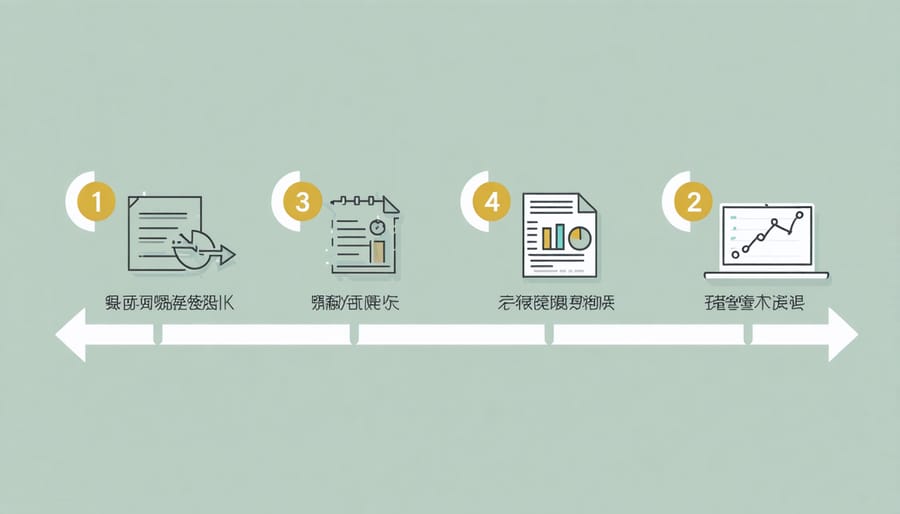

Strategic Implementation Framework

Assessment and Planning

Effective supply chain optimization begins with a thorough assessment of current operations and strategic planning for improvements. Start by analyzing key performance indicators (KPIs) such as order fulfillment rates, inventory turnover, and transportation costs. Canadian businesses should benchmark their performance against industry standards while considering unique regional factors.

Create a detailed map of your supply chain network, identifying bottlenecks and inefficiencies. Modern analytics tools can help visualize data patterns and highlight areas requiring attention. Consider implementing regular audit procedures to maintain ongoing assessment capabilities.

When planning improvements, prioritize initiatives based on potential impact and resource requirements. Focus on developing trade facilitation strategies that align with both immediate needs and long-term business objectives. Successful Canadian companies often begin with small-scale pilot projects before rolling out larger initiatives.

Remember to include stakeholder input throughout the assessment and planning process. This collaborative approach ensures buy-in from team members and helps identify practical solutions that work within your organization’s specific context. Regular review and adjustment of optimization plans keep them relevant and effective in today’s dynamic business environment.

Implementation and Monitoring

Successful implementation of supply chain optimization solutions requires a systematic approach and continuous monitoring. Start by establishing clear performance metrics and KPIs that align with your business objectives. These might include order fulfillment rates, inventory turnover, and transportation costs.

Canadian logistics expert Sarah Thompson of Supply Chain Canada recommends a phased implementation approach: “Begin with pilot programs in smaller segments of your operations before rolling out full-scale changes. This allows for adjustments and minimizes disruption to existing processes.”

Regular performance reviews are essential. Implement a robust monitoring system that tracks real-time data and generates actionable insights. Leading Canadian retailers like Lululemon attribute their supply chain success to rigorous monitoring practices and quick response to deviations from target metrics.

Consider creating a dedicated optimization team responsible for overseeing implementation and monitoring progress. This team should conduct monthly assessments, analyze trends, and make necessary adjustments to maintain optimal performance. Remember to maintain open communication channels with all stakeholders and provide regular training to ensure proper adoption of new systems and processes.

Supply chain optimization continues to evolve as a critical factor in business success, particularly for Canadian companies competing in the global marketplace. As demonstrated by industry leaders like Shopify and Canadian Tire, businesses that embrace advanced optimization strategies consistently outperform their competitors in efficiency, cost management, and customer satisfaction.

Looking ahead, emerging technologies such as artificial intelligence, blockchain, and Internet of Things (IoT) sensors will further revolutionize supply chain management. Canadian businesses are well-positioned to leverage these innovations, supported by government initiatives and a robust technology sector.

The key to successful supply chain optimization lies in maintaining flexibility while building resilience. Companies must focus on data-driven decision-making, sustainable practices, and strong partnerships across their supply networks. As global trade patterns continue to shift, businesses that invest in optimization tools and strategies will be better equipped to navigate challenges and seize opportunities.

For Canadian enterprises, the future of supply chain optimization presents both challenges and opportunities. By focusing on continuous improvement, technology adoption, and strategic partnerships, businesses can build more efficient, sustainable, and profitable supply chains that drive growth in an increasingly competitive global market.